Custom Product Enhancements

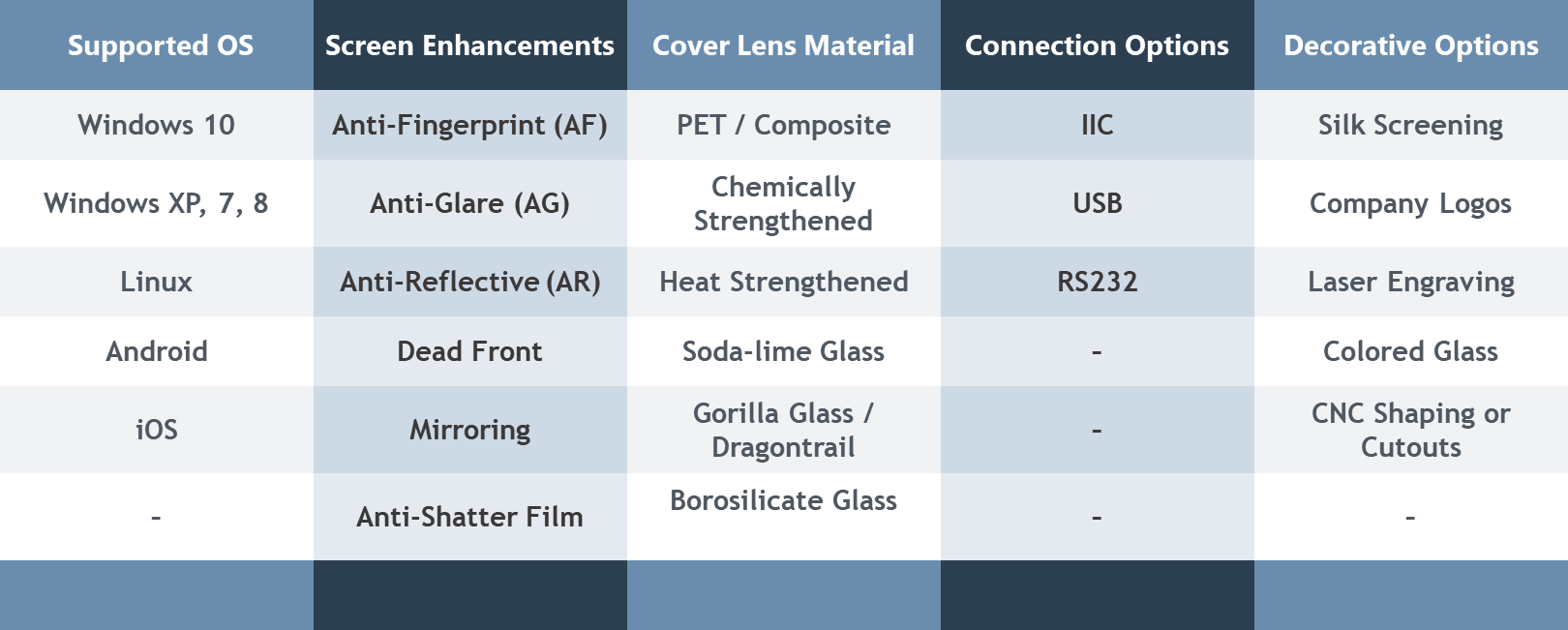

With such varied touch panel applications, product performance requirements vary just as much. Dignity has a wide range of product enhancements to provide improved and bespoke touch panel assemblies to meet those performance needs, no matter the standards set or the end application. From sun readability to customized cover lens design to panel sealing and ruggedization for the toughest environments, with more than 1500 different product solutions in our database, Dignity can offer valuable advice on how to optimize a touch solution for your needs. Here are some of the product enhancements we have on offer:

Material Selections

• Plastic Cover Lens – we offer a variety of plastic cover lens in order to reduce assembly weight and to improve product safety.

• Heat & Chemical Strengthening – our standard glass can be strengthened through heat tempering or through an ion exchange process; this will increase surface hardness and impact resistance (from 3 – 5 times normal glass).

• Gorilla Glass – We offer Corning’s Gorilla Glass® as well as the equivalent product from Asahi (Dragontrail glass) for exceptional strength, impact resistance and surface hardness (≥9H)

Cover Lens Customization

• Screen Printing – from 1-10 color screen printing of logos, company names and icons on the cover lens.

• CNC & Laser Cutouts – we can create cutouts for placement of hard buttons, membrane switches or other assemblies

• CNC Shaping – we can customize cover lens shape, bezel design and other aspects.

Screen Enhancements

• Anti-Reflection – an optical coating applied to the surface of the screen to reduce reflections. This improves display brightness, increases transmittance and can eliminate “ghost” ghost images. Essential for outdoor displays or those indoor displays with a high level of ambient light (for example point of information kiosks or digital signage).

• Anti-Glare – ideal for displays that require high resolution in poor conditions; reduces haze and improves display resolution. The most common screen enhancement, it is used for a wide variety of applications (ATMs, POS units, vehicles, etc.).

• Anti-Fingerprint – makes fingerprints less visible and easier to wipe off, as well as offering some scratch and water resistance. Ideal for touch screens with lots of handling (for example POS terminals).

• Anti-Shatter – A film that forms a nearly invisible protective coating on the glass surface. Pressure sensitive adhesives adhere glass shards together in case of breakage. Ideal for applications that require additional safety precautions.

• Anti-Fingerprint – makes fingerprints less visible and easier to wipe off, as well as offering some scratch and water resistance. Ideal for touch screens with lots of handling (for example POS terminals).

Dignity has an in-house team dedicated to firmware tuning in order to optimize your PCAP touch screen for its final application. Through tuning the IC’s firmware we can ensure optimal performance in a variety of conditions:

• Gloved Touch – touch panel will register touches even when the user is wearing gloves

• Presence of Water or Other Liquids– touch screen will operate even in the presence of liquid, which can confuse the IC and create false touches

• LCD Noise – by adjusting the IC to ignore the LCD’s electronic noise, we can ensure maximum touch sensitivity.

• Palm Rejection – the touch screen will reject “touches” by a user’s palm to present accidental inputs